This is the basic skill for a show you the tips and techniques of the skills involved with your mobile phone repair jobs today will go over the basic and advanced skills of Micro soldering tips and tricks.

Micro Soldering Repair Training

There are many kinds of mobile phone circuit soldering, but this article is designed to teach you the basics to advance smartphone and iPhone logical broad soldering. most repairs require you to have basic tools like a screwdriver or a sponge and others might involve more exciting tools like a soldering iron for microelectronics and a mobile soldering machine.

Before you read this blog post complete read mobile repairing tools name first! This page how to use mobile repairing tools to repair mobile phones gives you a cellphone repair tools free Review and a pdf guide on cell phone repairing tools list

Before you read this blog post complete read mobile repairing tools name first! This page how to use mobile repairing tools to repair mobile phones gives you a cellphone repair tools free Review and a pdf guide on cell phone repairing tools list

Now Review the Tools for Soldering Microelectronic Components

Iron Tip: Most electronics mobile repairing soldering iron and soldering station have interchangeable tips, the iron tip is also known as the bit. Click here to see the iron tip today price

Apart from Micro soldering tips, you may also need a few other tools like a sponge, iron stand, safety goggles, PCB holder, solder wire rosin core, desoldering wick remover wire, and soldering flux paste. how can you actually use this?

|

| mobile repair tool list |

|

| Micro Soldering Training pdf |

Sponge: Something with which to clean your tip like a wet water sponge or wet cotton. see the sponge price and where to buy details here.

|

| soldering iron sponge |

Safety Goggles: Especially if you're a beginner, you should be wearing safety goggles. buy affordable safety goggle that suit your anti-fog soldering here

|

| safety goggles amazon |

PCB Holder: Suitable for fixed maintenance of smartphone circuit board and small essential for mobile phone maintenance easy to use, make your repairing work smooth. buy a high-quality PCB Holder a less expensive and affordable one. view today price here

Solder Wire Rosin Core: For a good solder joint between two components, you need the best quality of solder wire. solder wires are available in different diameters. solder wire rosin core is the most common and widely used solder wire. to know affordable solder wire prices click here

|

| rosin core solder |

Soldering Flux Paste: Apply the best quality solder flux on the area of the leads of microelectronic components to be soldered. soldering flux paste will help to remove any deposited oxides from the surface of the microelectronic metals thus leading to better solder joints. to know the best Soldering Flux Paste price before buying click here

what is soldering and why do we do it? the best answer

|

| best definition |

Soldering is a method of connecting electronic components and their copper print on a PCB together by melting another filler metal in between them. Why would you need to join two copper layers together? Typically the common uses of solder are when a copper wire or component print gets cut and needs to be "fused" jumper back into the circuit.

Now we have all the tools we need to start doing soldering by hand so let's jump into it right now. The best part?

Cleaning: When the iron tip burnt flux accumulated on it, solder no longer wet the iron tip,

then impending heat transfer and making soldering SMD components with soldering iron difficult or impossible.

the tip must be periodically cleaned when using. Such problems happen with all kinds of soldering iron tips, A wetted water sponge or cotton can be used to wipe the tip for more aggressive cleaning

Iron Tip Care and Maintenance: For soldering iron coated with a thin of solder.

|

| care thin of solder |

allow the iron to transfer the heat to the workpiece on the PCB. This procedure is called iron tip tinning.

|

| The solder iron tip works fine |

|

| solder wick |

Hand Soldering and Micro Soldering Training

|

| practical guide |

Hand soldering is done for repairing faulty mobile printed circuit boards and components. sometimes repairing and replacement of SMD components is also done by hand in mobile repairing jobs. hand soldering basic is done during PCB rework in a production unit when a smartphone PCB gets smash crash damage. by hand, soldering is also done for repairing and servicing printed circuit boards by the mobile technician. some mobile technician uses mobile soldering machine. hand soldering is useful when replacing components on PCB with other PCB.

|

| what they do |

Smartphone and iPhone basic electronic: Smartphone motherboards, tablet, Mac, iPod, iPad, and iPhone logical boards are filled with basic electronic components, many of these components such as coils, resistors, capacitors, and FPC, LVDS connectors are specification different models and brands. sometimes those components get failed due to water damage or a phone being dropped by the customer's basic electronic get disconnect from the copper prints. When these components are disconnected from the iPhone logical board or have been damaged by the user then you will need to perform micro-soldering repairs.

Demonstrate how to sold micro components with the soldering iron: Make sure the soldering iron is hot. Do not touch it. Hold the soldering iron properly in one hand and the component in the other hand with the help of a tweezer. Maintain proper angle between component and PCB. by joining two surfaces allows the DC current to flow from one component to another microelectronic by print. Place the component at the copper track on the PCB with the help of the tweezer.

|

| works quickly |

Apply heat where the lead of the component meets the copper track on the PCB. and hold the component with the tweezer.

|

| micro soldering flux |

Anti Static ESD Brush for Cleaning Mobile Phone Tablet PCB BGA Repair Soldering: Antistatic brush is best for cleaning all Dusting and Dirt from sensitive components and FPC connectors safely. suitable for cleaning, washing, and removing any liquid from the surface of iPhone and Samsung mobile phone PCB. The brush cleans those areas which are hard to reach in PCB, with its long handle and soft hair brush that are easy to use.

|

| Cleaning Mobile Tablet PCB |

You can also use soldering tweezers iron an advanced tool for soldering, resoldering basic electronics

For soldering and desoldering small surface-mount components like resistors, polar or non-polar capacitors, and Zener diodes, tweezer-style soldering iron can be used, with two terminals and free-standing or controlled from a soldering station. soldering tweezers iron is also called tweezer soldering iron SMD. The tweezers have two heated tips applied to the two ends of the PCB component. The main purpose of the soldering tweezers is to melt solder around the components. in this new era of smartphone repairing at your mobile repair shop, you need to perform micro soldering repairs at the microscopic level.

|

| tweezer soldering iron |

Micro Soldering For iPhone Cell Phone Mobile SMT Repair Right Now

With the latest tools and the right knowledge, it is possible to repair costly iPhone, Samsung, and tablet motherboards at the component and chip level. This process is called “micro soldering” Once you are ready with all the tools needed for Micro soldering, you are ready to start the iPhone repair job.

|

| micro soldering training |

iPhone Board Level Repair: So, what does it take to learn hand soldering microelectronics and component level repair? The best place to start is with the micro soldering flux and soldering micro resistor. start by making sure the iPhone logical board and the leads of the components are clean and free from any dust or grease. microelectronic components which are not clean may have deposited oxides that can lead to bad solder joints.

|

| micro soldering flux clean microelectronic |

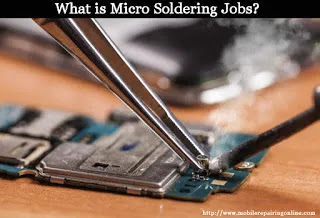

What are Micro Soldering Jobs?

During your repair process, you would perform an initial examination of the device motherboard, inspect for damage externally, then proceed to view the board with the components under a microscope to see problems. anything repaired and soldered under a microscope would be also considered "micro soldering jobs". the iPhone's logically broad components and ICs get to a smaller size often times soldering on microcircuits is needed, typically working with the smaller components using standard tools is very difficult. you can’t learn to solder all microelectronics without a microscope. In this article, we will go over choosing the best microscopic and tweezers iron, as well as everything else you will need to learn micro soldering jobs and take your smartphone repair business to the next level. let's suppose you are earning an average of $70 per repair on a cell phone and you do 10 FP(feature phone) repairs each week, that’s revenues of $700 weekly. when you do SP(smartphone) repairing you can earn an average of $90 per repair on a smartphone, tablet, Mac, iPad, iPod, and iPhone logical boards by micro soldering repair equipment. your weekly business revenue percentage can increase by 100%

|

| phone microscope attachment |

Microscope with Magnifier: Microscope used to see a magnified view of the Device PCB, FPC connectors, or microelectronic components. with the microscope can easily see and work with iPhone and other smartphone motherboards, generally, eyepieces provide the microscope to see the magnification. magnifier available in different zoom options. the best quality microscope eyepieces can be swapped for higher or lower magnification. There are different attachable light sources available for a microscope as well. Ring lights source can attach to the bottom of the microscope and provide lighting around the workspace.

|

| microscope smartphone magnification view |

you can add a camera to your microscope. the camera is a great way to show customers exactly what sort of repairs need to be made on their smartphone circuit as well as teach other technicians logic board level repair. The most important feature of the microscope is the glass. microscopes can be connected to a computer LED.

|

| camera view feature |

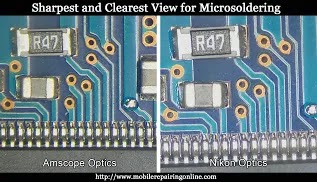

you can find the sharpest and clearest view from Amscope and Nikon lenses. In practice, the scope it’s fine for all smartphone motherboard micro soldering work I’ve done.

I hope all of the above board-level repair step-by-step picture help was useful enough to explain Micro Soldering Repair. If you have any questions then feel free to ask via the comments below

Post a Comment

Post a Comment

please dont add any spam comment